- Using SafetyCulture

- Assets

- What are assets?

What are assets?

Learn more about assets in SafetyCulture and how to organize, track, and maintain the tools and equipment your team relies on.What are assets?

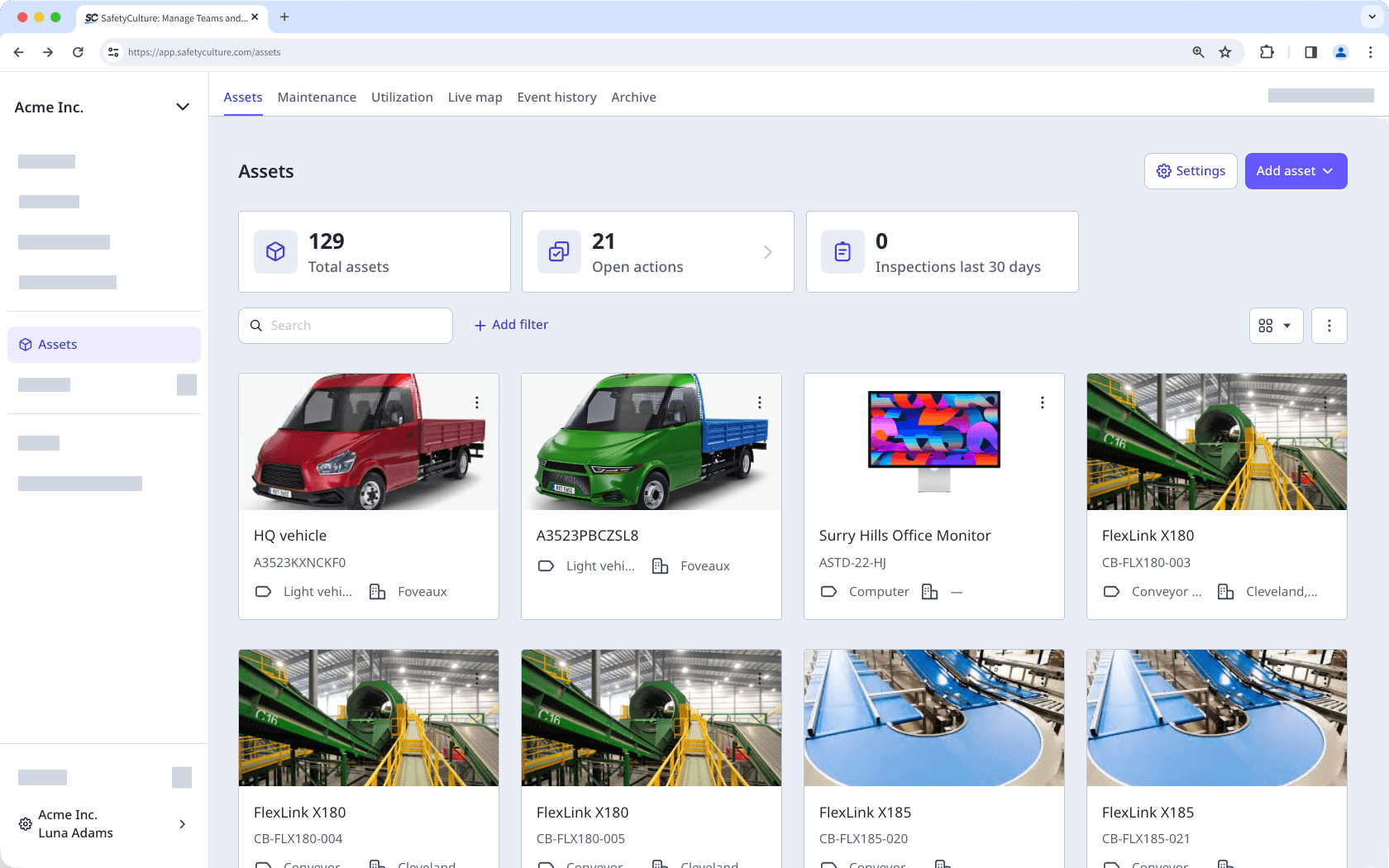

Assets can be anything your team needs to track and maintain like machinery, vehicles, safety gear, facilities, or even tools used in day-to-day operations. The Assets feature in SafetyCulture helps you manage these items in one place, where you can organize them by type and site, capture key data through inspections or integrations, and connect them to actions and maintenance workflows. With bulk asset management, offline access, location tracking, and usage monitoring, you gain full visibility and control across your operations. From scanning assets in the field to automating maintenance based on readings, the feature is built to support consistent, reliable asset management at scale.

Assets in SafetyCulture

Custom types and fields

Assets in SafetyCulture represent physical equipment, vehicles, and other areas or items that are important to your operations. You can define your own asset types like generators, fire extinguishers, or delivery trucks to suit your organization's needs. Each type can include custom fields, such as VIN, fuel type, and warranty dates, to standardize asset information and capture the most relevant details for you.

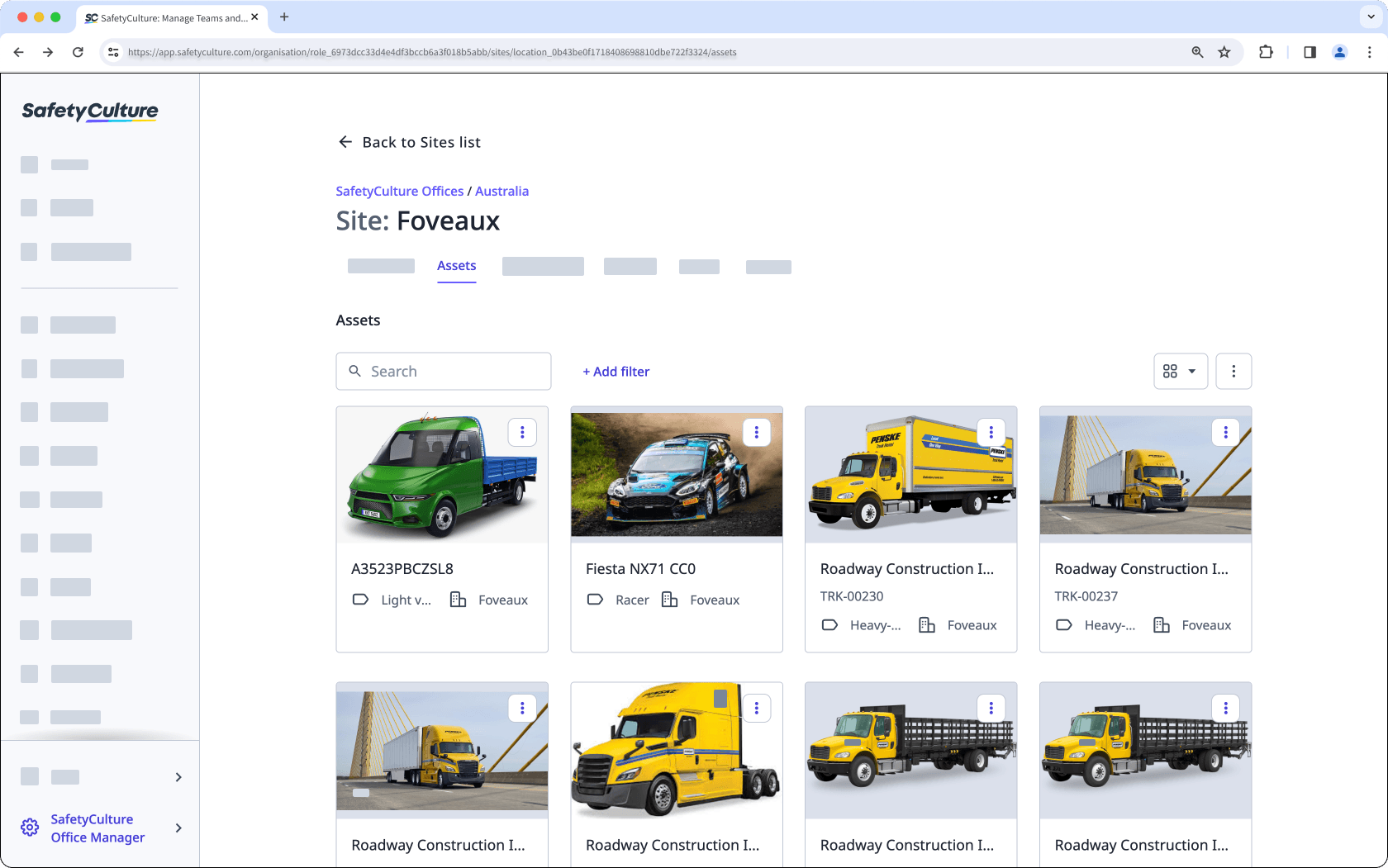

Site assignment and access control

Assign assets to sites individually or in bulk to help organize them by physical location, department, or region. This also controls who can view and manage assets based on site memberships.

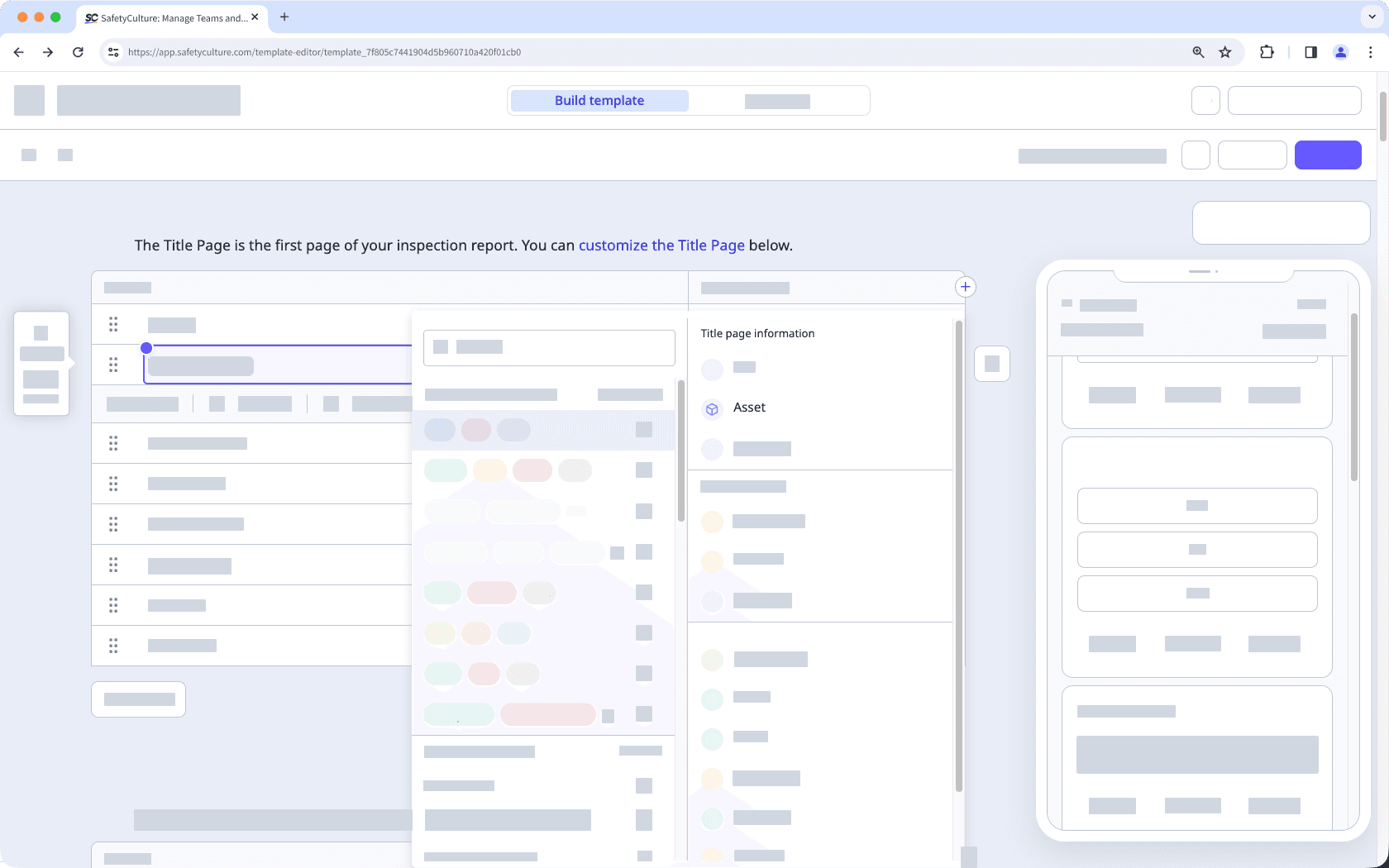

Connect assets to templates and inspections

Templates and inspections can be associated with specific assets by adding an asset question. You can also schedule regular inspections for your assets to help teams perform proactive, periodic checks. For example, you can consistently capture readings and other details about the same asset each time you use the template. This setup not only improves traceability, it also helps uncover trends, prevent recurring issues, and keep assets performing at their best.

Overseeing multiple asset templates? Quickly manage all templates with asset questions, including asset types and readings from the Assets settings page.

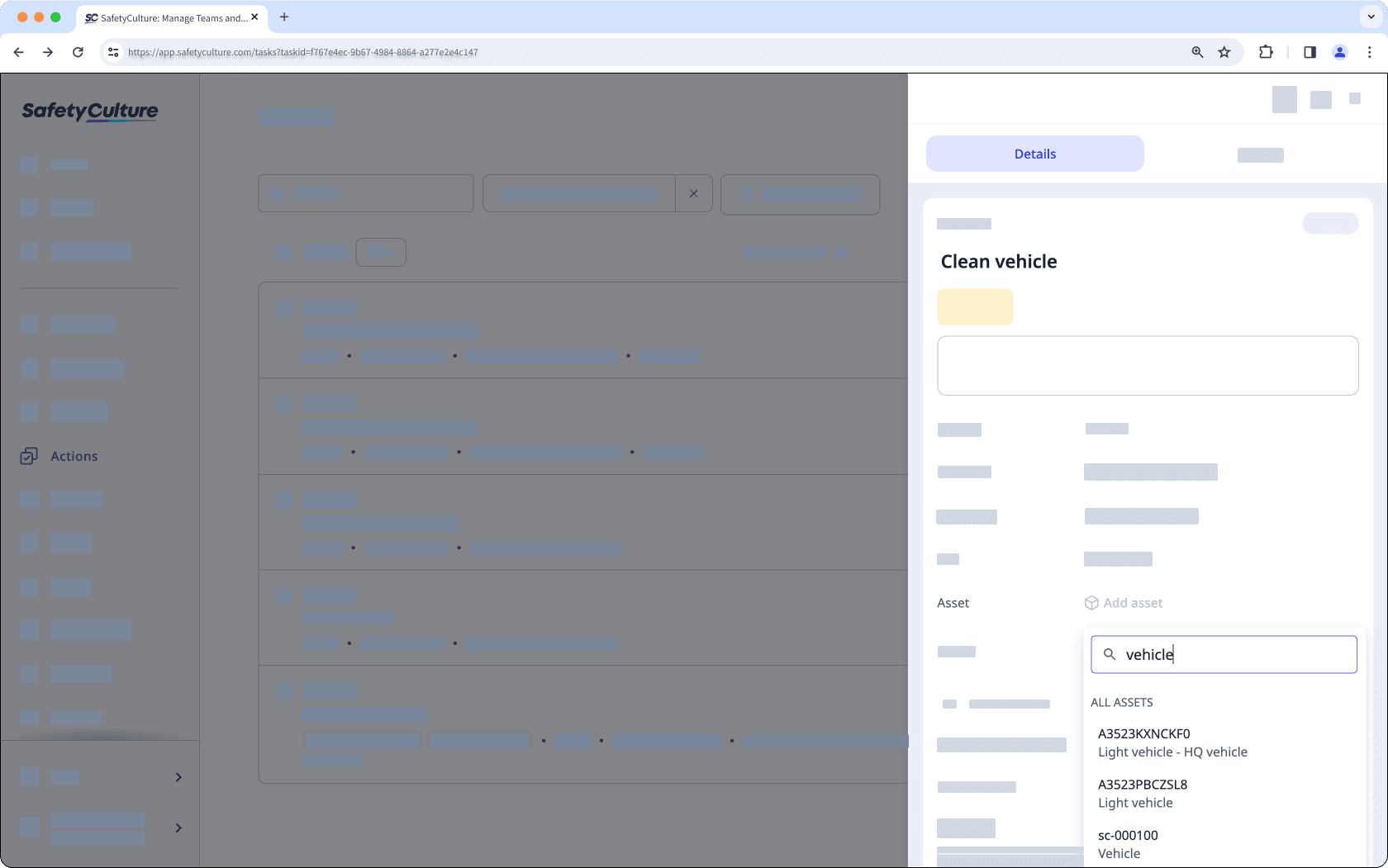

Create actions for assets

Flag repairs, servicing needs, or other required follow-ups by creating actions and even recurring ones for your assets. This way, you can easily track what's been raised, by whom, and when. It helps teams respond faster and gives you a clearer picture of asset reliability, so you can stay ahead of potential problems and make confident maintenance decisions.

Bulk asset management

Managing assets one by one can be time-consuming. Bulk management lets you add or update multiple assets at once via CSV. It's useful for onboarding existing equipment, standardizing asset data, and applying changes efficiently across your records.

Scan assets in the field

Scanning helps teams quickly access the right asset in high-paced environments. Each asset can be assigned a unique barcode or QR code, which your team can scan using the SafetyCulture mobile app. This instantly brings up the asset during inspections or when creating actions, removing the need to manually search.

Using RFID tags? You can scan them in the field with supported Zebra devices to instantly open matching assets.

Track assets

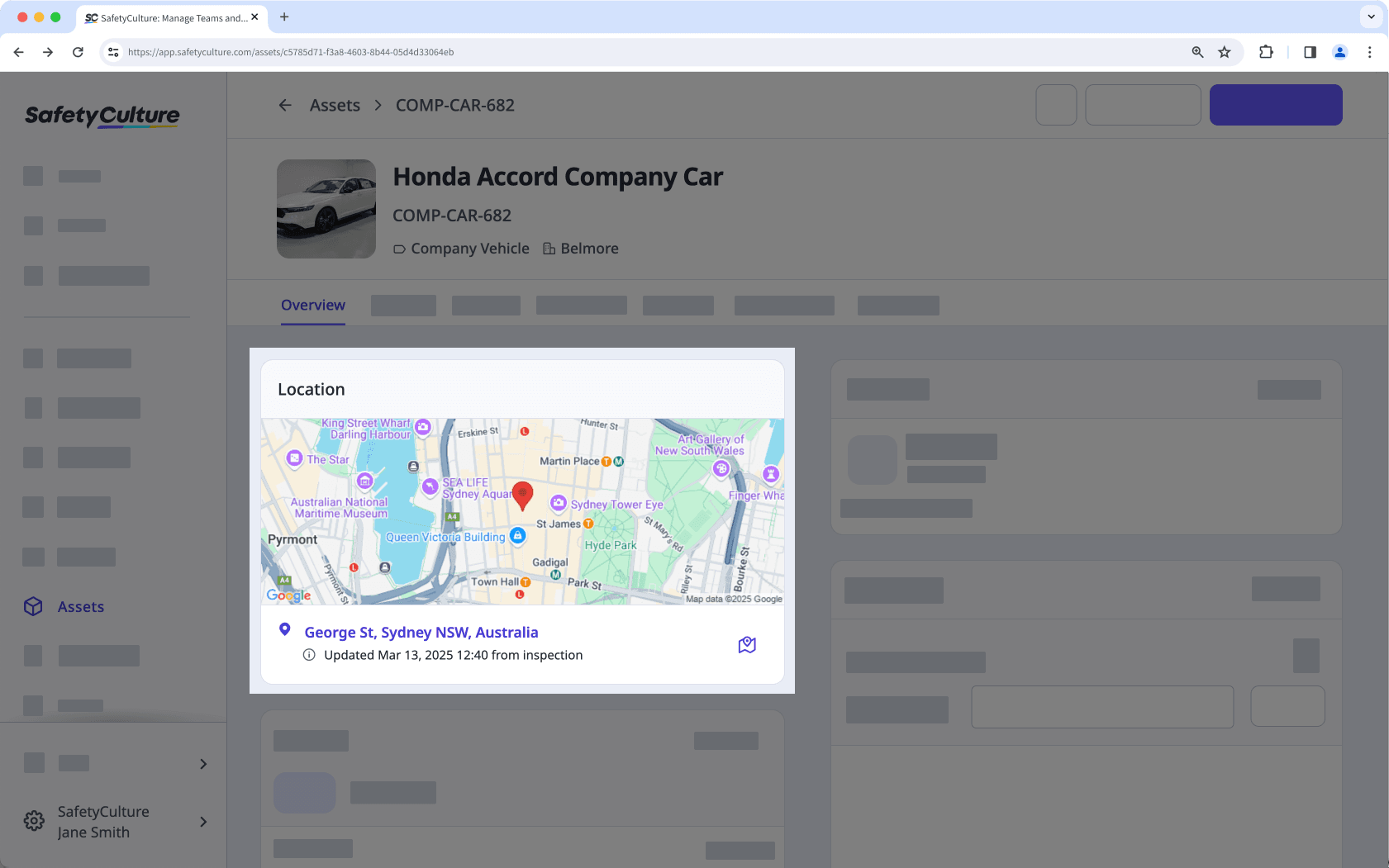

You can monitor asset locations in SafetyCulture using inspection data and connected telematics systems. Use the Live map to view real-time asset locations, the Event history to review past movements and reported activity, or the last known location to quickly reference the most recent position of any asset. Each view supports different tracking needs and helps teams locate and manage assets with confidence.

Work offline

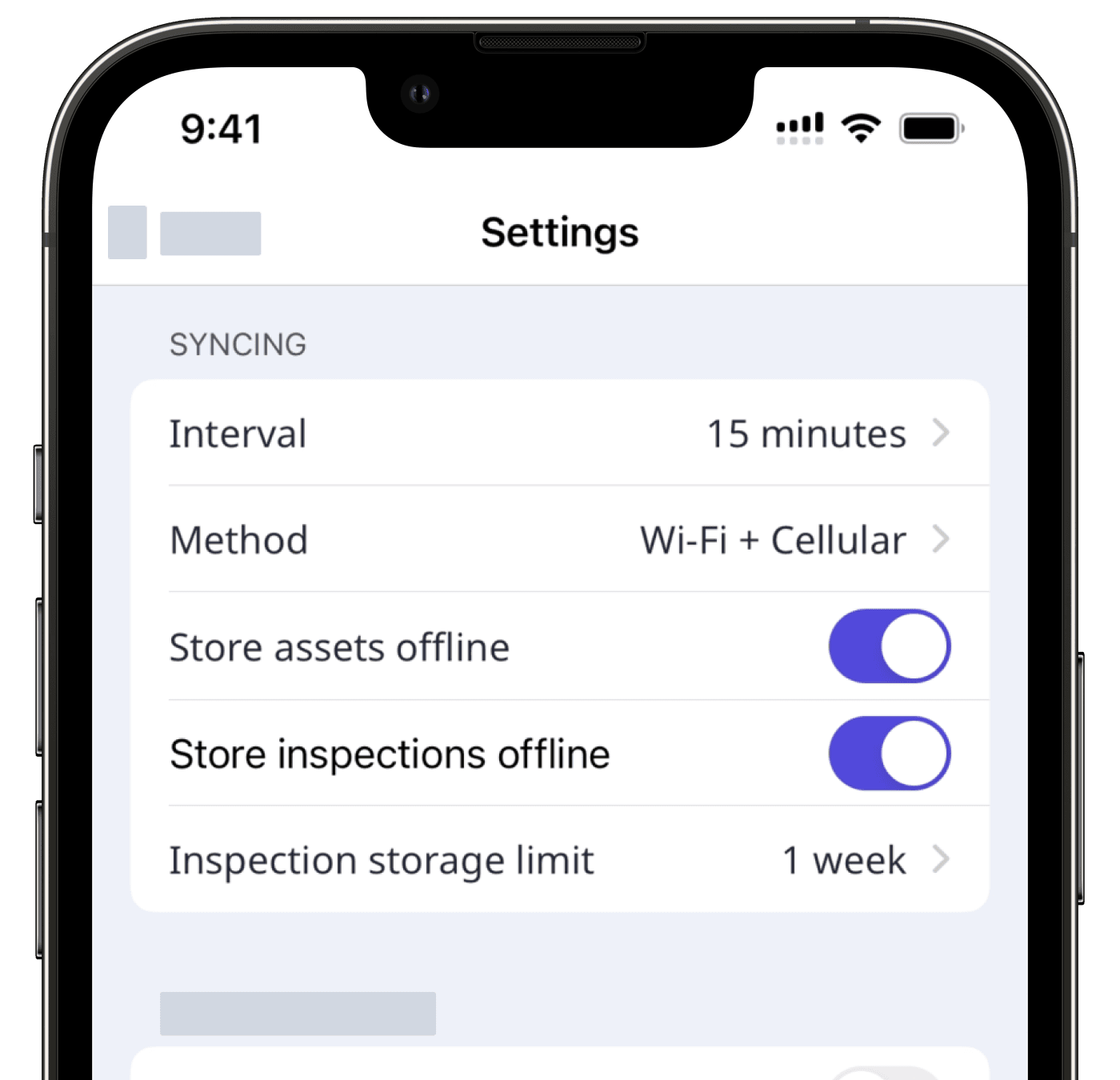

You can still access and work on your assets even when you're offline. With the SafetyCulture mobile app, you can view asset details and conduct inspections easily. Any changes you make will automatically sync once you're back online, ensuring your team can stay connected while on the field or in remote areas.

Capture asset readings

Assets can store important readings depending on how you've set them up. You can enter these manually via inspections or automatically via integrations with telematics providers. Tracking these readings over time helps monitor performance, identify problems early, and schedule servicing based on real usage.

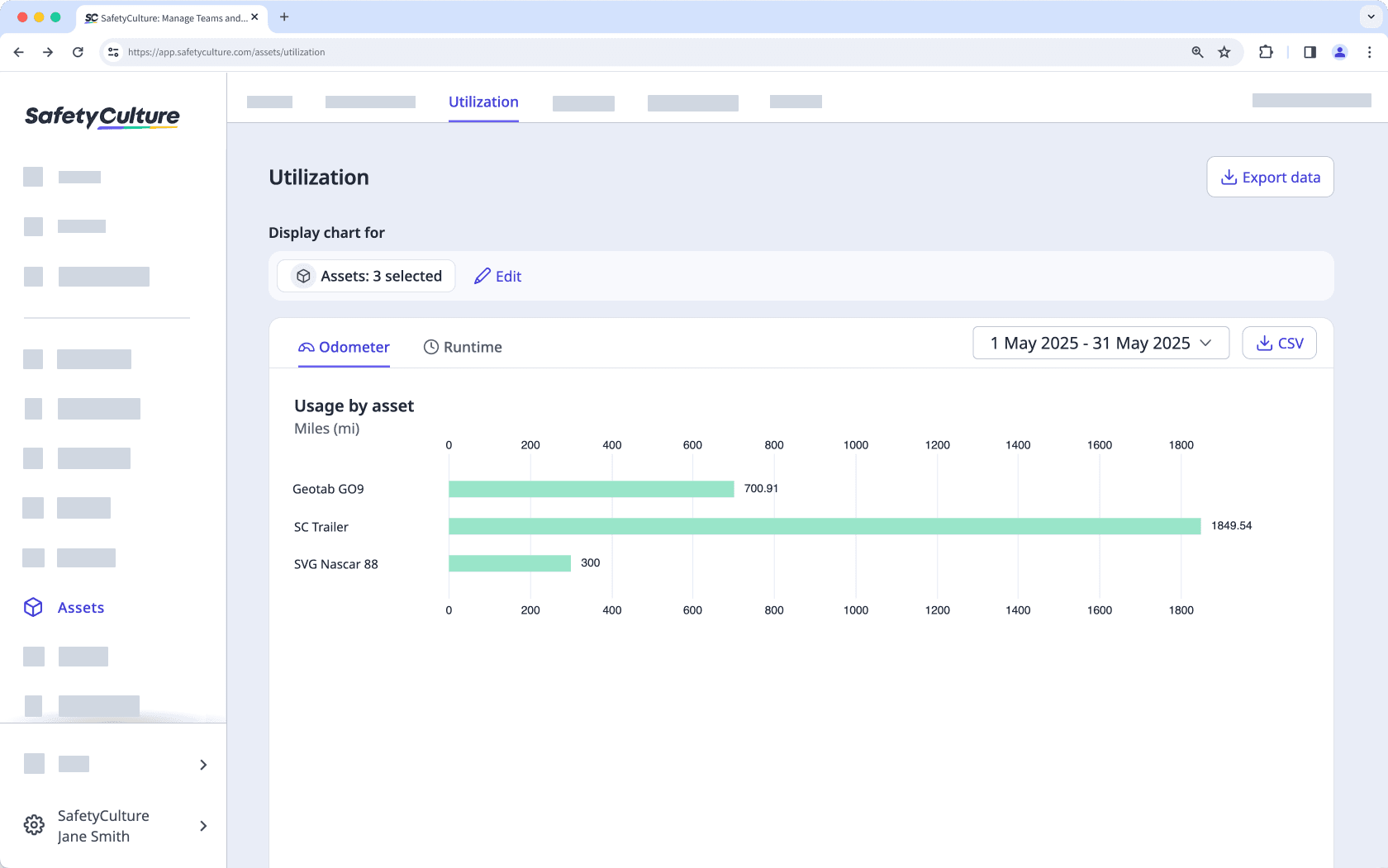

Asset utilization

Track how effectively your assets are used by reviewing associated readings over time. Asset utilization charts in SafetyCulture visualize this data to help you spot usage trends and identify underused assets. You can export this information as a CSV to support planning, improve maintenance strategies, and make more informed decisions.

In Analytics, you can group and filter data by specific assets or asset types, allowing you to confidently find the insights you need.

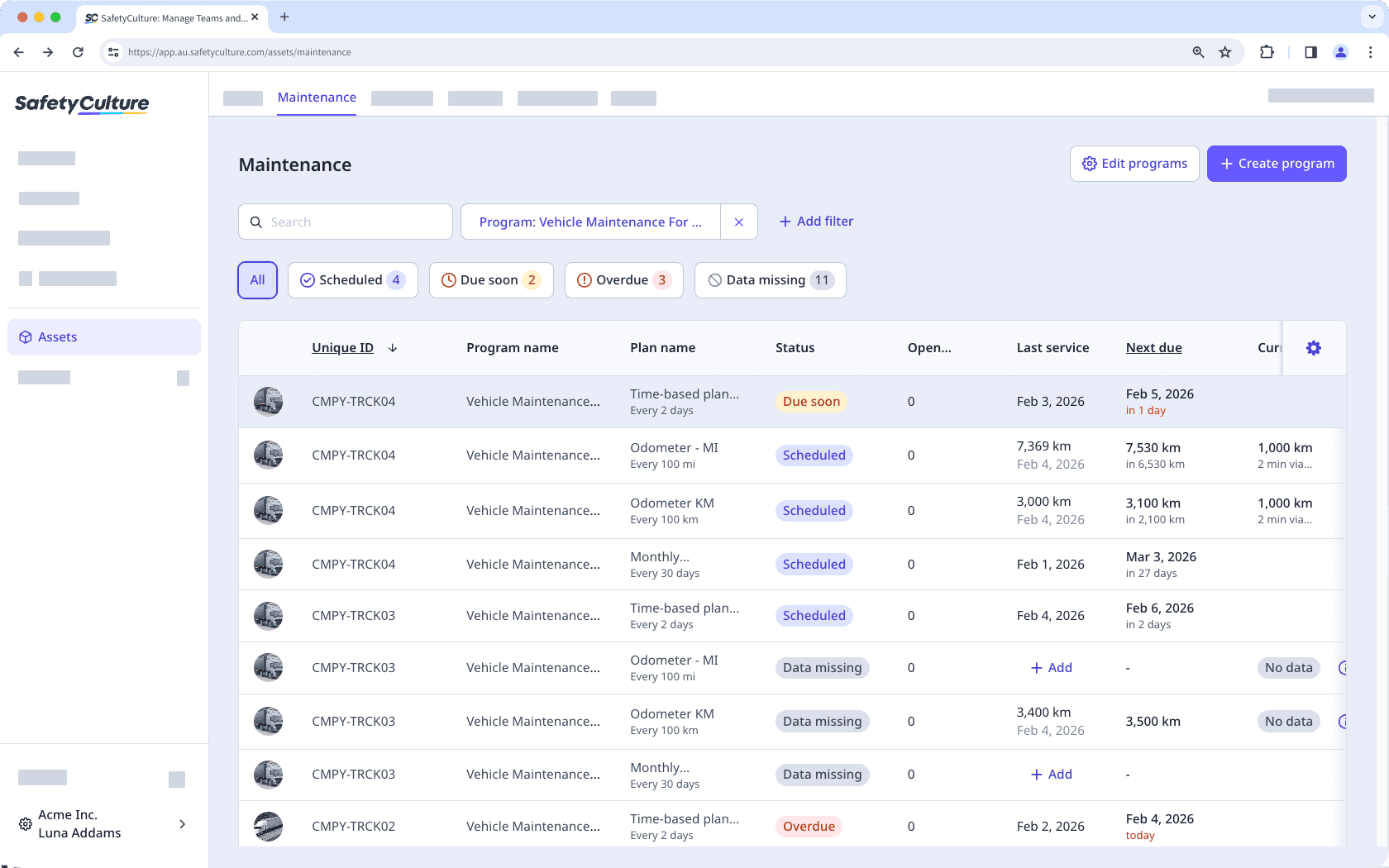

Preventative maintenance

Schedule maintenance based on how often assets are used or how much time has passed since their last service. In SafetyCulture, you can create usage-based or time-based plans that trigger when an asset reaches a set odometer reading, runtime total, or time interval. These plans can also send automated notifications to keep your team informed and ready to take action when maintenance is due.

Was this page helpful?

Thank you for letting us know.