- Using SafetyCulture

- Asset maintenance

- What is preventative asset maintenance?

What is preventative asset maintenance?

Learn more about how you can plan, monitor, and carry out preventative maintenance for all your assets in SafetyCulture.The preventative asset maintenance feature is currently in Early Access. If you're interested, go to the web app, select Assets from the menu on the left-hand side. Select Maintenance from the tab at top of the page and click Get Early Access.

Is Maintenance not in your menu? Reach out to your Customer Success Manager to express your interest.

What is preventative asset maintenance?

Preventative asset maintenance keeps vehicles, equipment, and machinery running smoothly through regular, scheduled servicing. This proactive approach extends your assets' lifespan and ensures they perform consistently to support your daily operations. It also allows you to identify and address maintenance needs early, such as replacing worn brake pads, topping up fluids, or changing filters before they affect performance. Overall, preventative maintenance creates lasting value that allows you to protect your investment, control expenses, and improve operations across your organization.

SafetyCulture simplifies this process by organizing maintenance into programs and plans that schedule work based on asset usage or time intervals. With clear visibility and automated notifications, your team can manage maintenance tasks confidently and on time.

Exploring preventative asset maintenance in SafetyCulture

In SafetyCulture, administrators manage programs and plans from the Assets settings, while team members use the maintenance table to view schedules, log service details, and take action. This clear division of responsibilities supports efficient day-to-day maintenance while ensuring control and visibility.

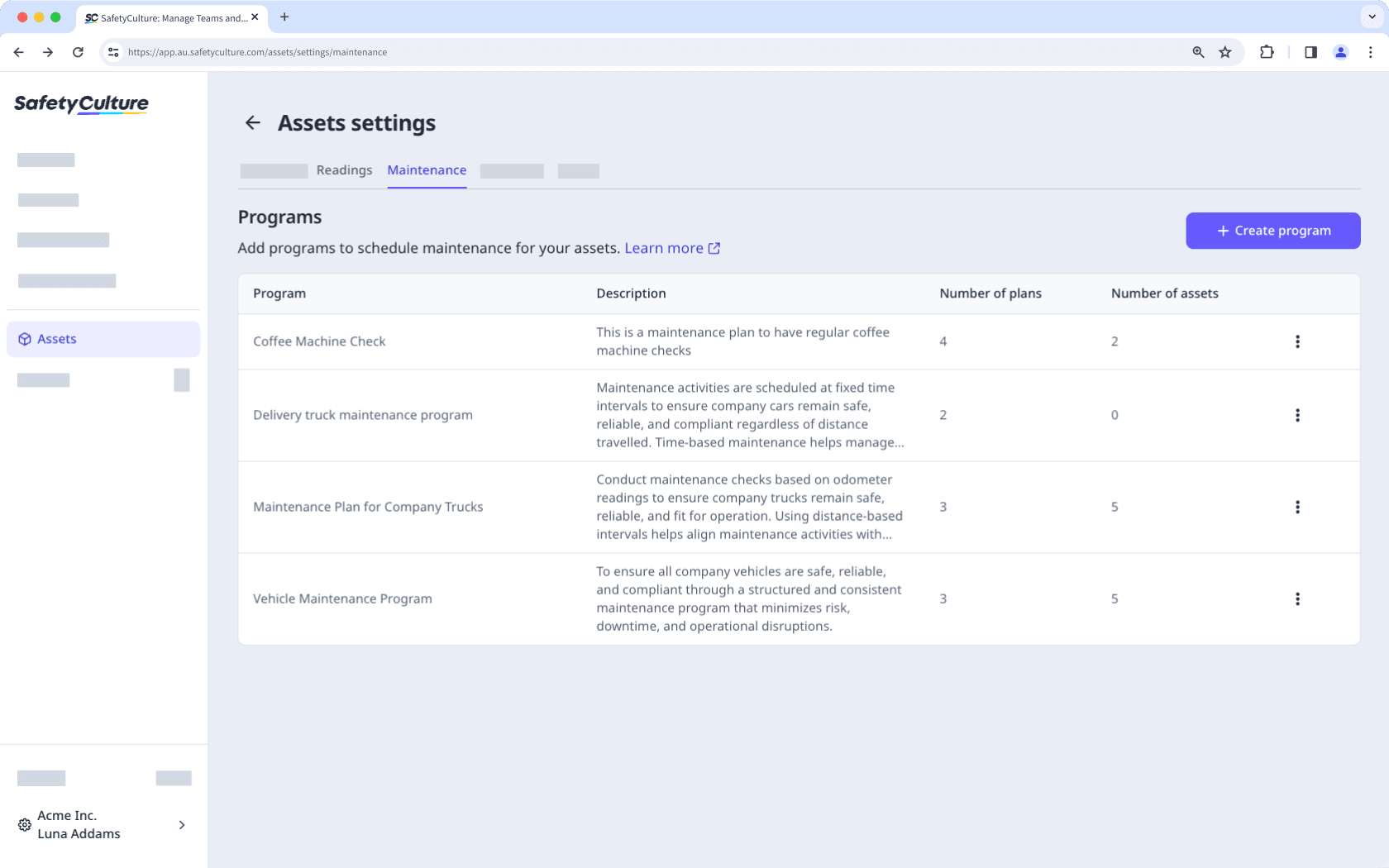

Programs

Programs group related maintenance plans under a shared schedule, such as “Weekly safety checks” or “Warehouse equipment servicing.” Within each program, you can include multiple plans, assign assets, and even record last service details to ensure data accuracy and continuity.

Plans

Asset maintenance plans are servicing schedules that help your team keep your assets in good working condition. In SafetyCulture, these plans can be time-based, usage-based, or a combination of both.

Time-based plans trigger maintenance at fixed intervals, such as every 5 days, regardless of asset use. These are ideal for routine checks that meet safety, regulatory, or operational standards.

Usage-based plans trigger maintenance based on actual asset use, such as every 1,000 kilometers or 250 hours. These are better for equipment with varying usage patterns, like generators or fleet vehicles.

You can assign multiple plans to an asset, depending on its maintenance needs. Define the interval and set alert thresholds so teams know when maintenance is scheduled, due, or overdue. At least one notification must be set up to inform users when they need to complete service-related actions.

With asset utilization, you can determine how effectively your team uses assets in your organization and adjust maintenance plans based on real data. Combine both features to make data-informed decisions that keep your assets running efficiently.

Each plan requires last service details to calculate when the next service is due. The system updates the plan's status automatically using this information, and you can monitor it from the maintenance table, which highlights if data is missing or out of date.

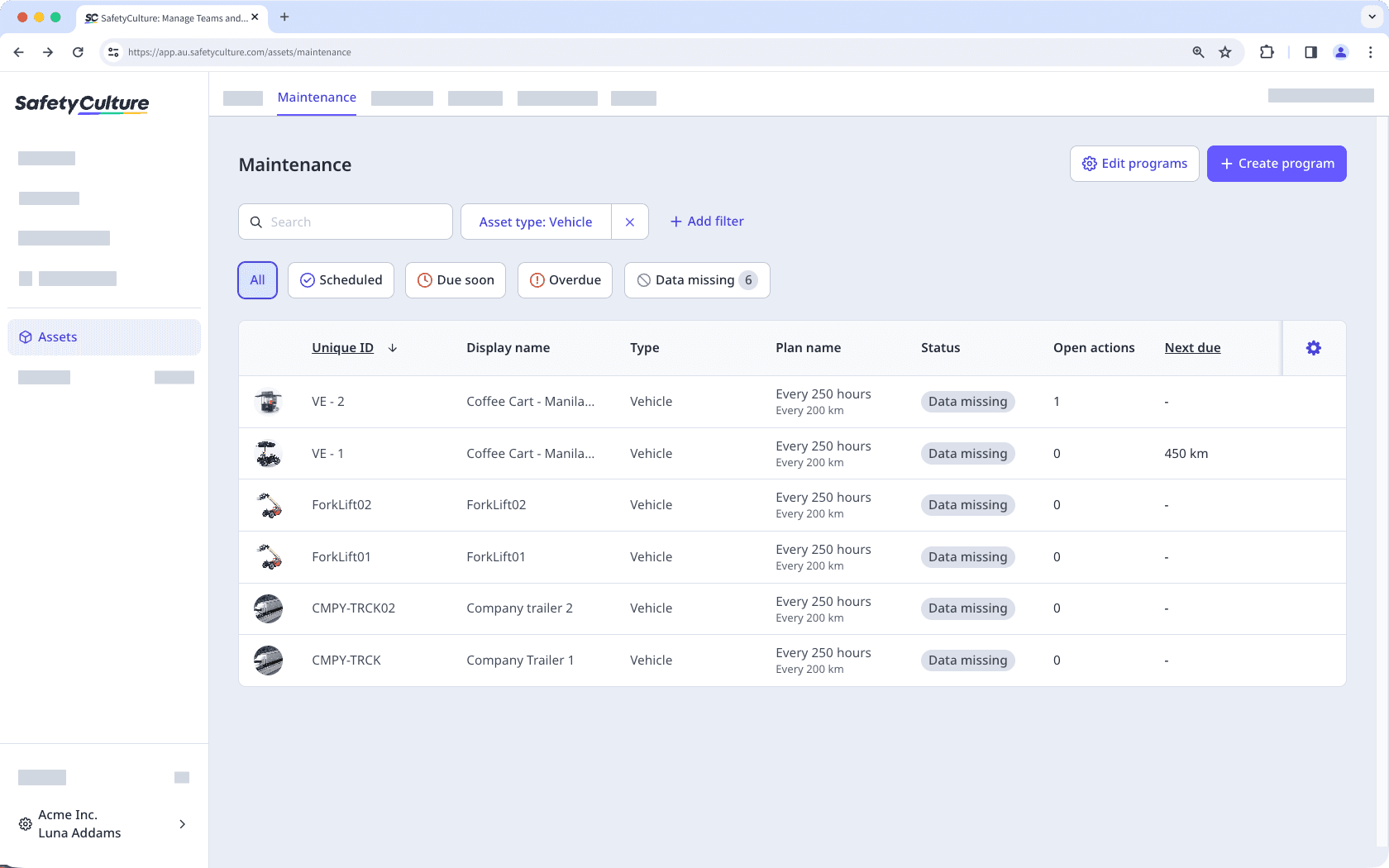

Maintenance table

The maintenance table gives you a centralized view of every plan in your organization. You can use it to identify which assets need attention, check plan types and frequencies, add last service details, and stay ahead of maintenance schedules.

In addition, you can create actions directly from the maintenance table to assign and track service tasks at any point. This ensures maintenance is planned, visible, and completed efficiently to maximize asset health.

By default, the table displays six key details: unique ID, plan, status, last service, next due, and current reading.

Field | Description |

|---|---|

Unique ID | This shows the unique identifier of an asset. Depending on how your organization catalogs assets, it could be a fleet number, registration code, equipment label, or custom ID. The same unique ID may appear multiple times if the asset has more than one active plan. |

Plan name | This shows the maintenance plan applied to the asset, including how often it occurs. For example, "Oil change Every 10,000 km". Plan names are defined during setup and usually describe the maintenance task that needs to be completed, such as “Engine check” or “Flush and replace oil". Then, frequency depends on a time-based interval (like every 8 weeks) or a usage-based threshold (like every 10,000 mi or 250 hr). |

Status | This shows the current state of a maintenance plan based on recorded service data and thresholds. Statuses help your team prioritize which maintenance plans need attention now, which are approaching, and which lack required data to stay on track. The following statuses dynamically update as usage increases or time passes. • Scheduled: The plan is active but not yet due. No action is needed yet, but keep monitoring until it is due. • Due soon: The plan is nearing its threshold and will require maintenance soon. Prepare to complete the maintenance and ensure the current reading is updated. • Overdue: The plan has passed its scheduled time or usage threshold and needs immediate attention. Record maintenance as soon as possible to keep the plan on schedule and update the last service value. • Data missing: The current reading, last service details, or both haven’t been recorded yet, so the system cannot determine when the plan is next due. Enter the missing values to track the plan's status and next service accurately. |

Last service | This shows the most recent recorded odometer, runtime, or date you conducted the last maintenance. Based on a time or usage threshold, this value calculates when the plan is next due. Enter the last service value to activate the plan and set a starting point for tracking maintenance. For existing plans, updating the last service ensures the next due threshold is accurate and reflects the most recent maintenance performed. If you haven't recorded the last service value yet, the system can't calculate when the plan is next due, and the plan status will show as Data missing. |

Next due | This shows when the next service is expected, based on time or usage thresholds. The value is automatically calculated using the last service and current reading, and appears blank if any required data is missing. • For usage-based plans, the system calculates how much distance or runtime remains until the next service by comparing the last service reading with the current reading and the plan’s threshold. For example, if the plan repeats every 10,000 km and the last service is 10,000 km, the next due is 20,000 km. The system checks the current reading to show how close you are to that point. • For time-based plans, the system uses the last service date and adds the interval to calculate the next service due date. For example, if the last service was on March 1 and the plan is every 8 weeks, the next due is April 26. |

Current reading | This shows the most recent odometer or runtime value recorded for the asset. You can track readings using inspections, connected GPS devices, or telematics integrations. This column displays No data if no reading has been recorded yet, and it remains empty for time-based plans where a usage reading isn’t required. |

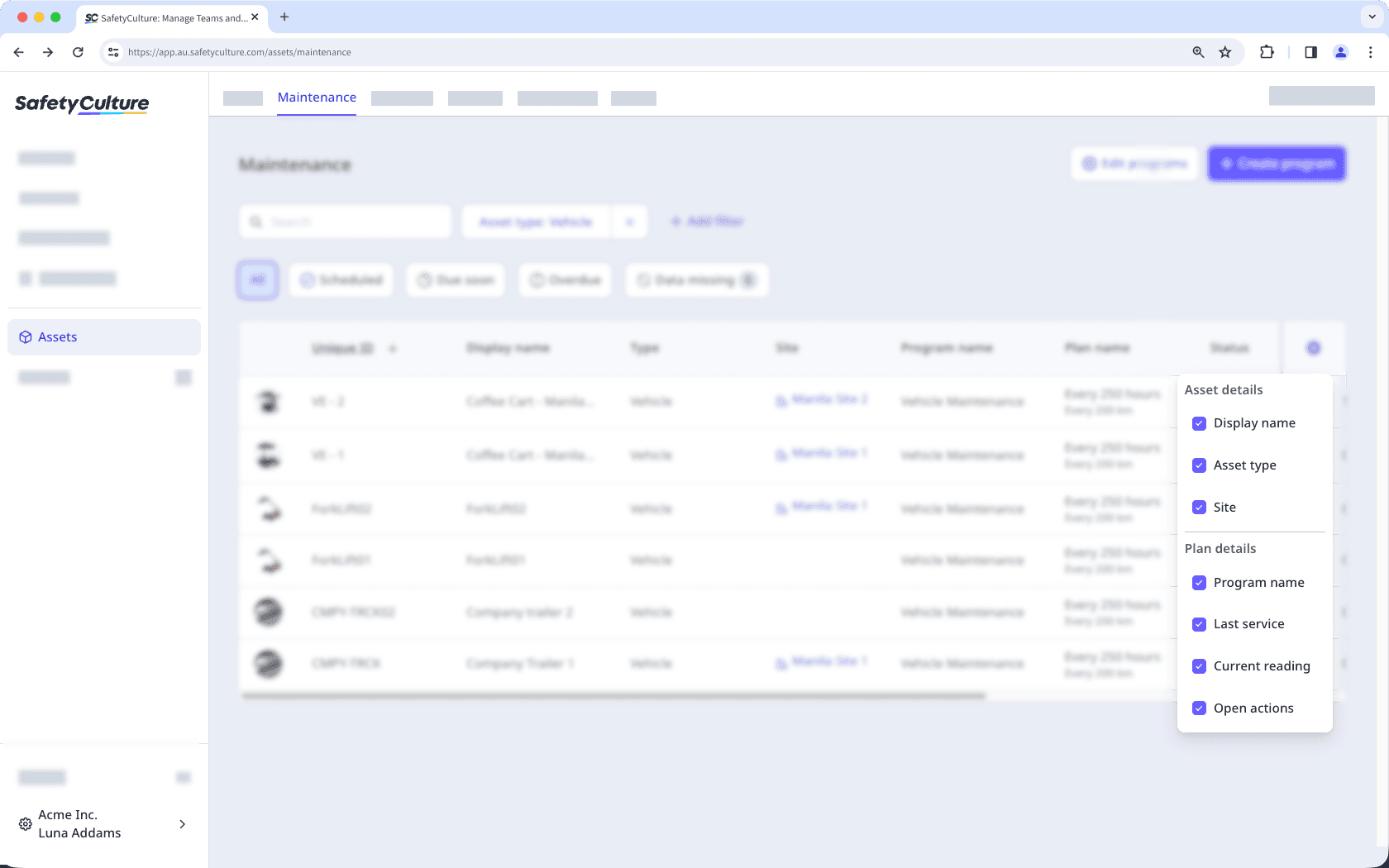

You can also view additional asset or plan details on the maintenance table.

Field | Description |

|---|---|

Display name | The display name of the asset. |

Asset type | The type of the asset. It is useful for filtering plans by asset category. |

Site | |

Program name | The name of the maintenance program that the plan belongs to. |

Open actions | This shows the number of open actions that are tied to the maintenance plan. |

The asset profile brings together maintenance plans, usage data, and and every important detail in one place. Use it to better understand how each asset is maintained and performing over time across your organization.

Was this page helpful?

Thank you for letting us know.