- Utiliser SafetyCulture

- Maintenance des actifs

- Qu'est-ce qu'un statut de plan de maintenance des actifs ?

Qu'est-ce qu'un statut de plan de maintenance des actifs ?

Découvrez-en davantage sur les statuts des plans de maintenance et comment ils aident votre équipe à suivre l'entretien des actifs, à réduire les retards et à gérer plus efficacement les interventions de maintenance.What are asset maintenance plan statuses?

Maintenance plan statuses show where each asset is in its maintenance cycle. These serve as early warnings that show how close each asset is to needing service, whether it's coming up soon, already overdue, or missing required information. In SafetyCulture, these statuses are automatically assigned based on time or usage thresholds that you define when setting up your plans. Each status helps your team take action at the right time and supports preventative maintenance decisions at every level. For example, technicians can see what work is coming up, managers can prioritize maintenance based on urgency, and organizations can keep critical equipment available when it's needed most.

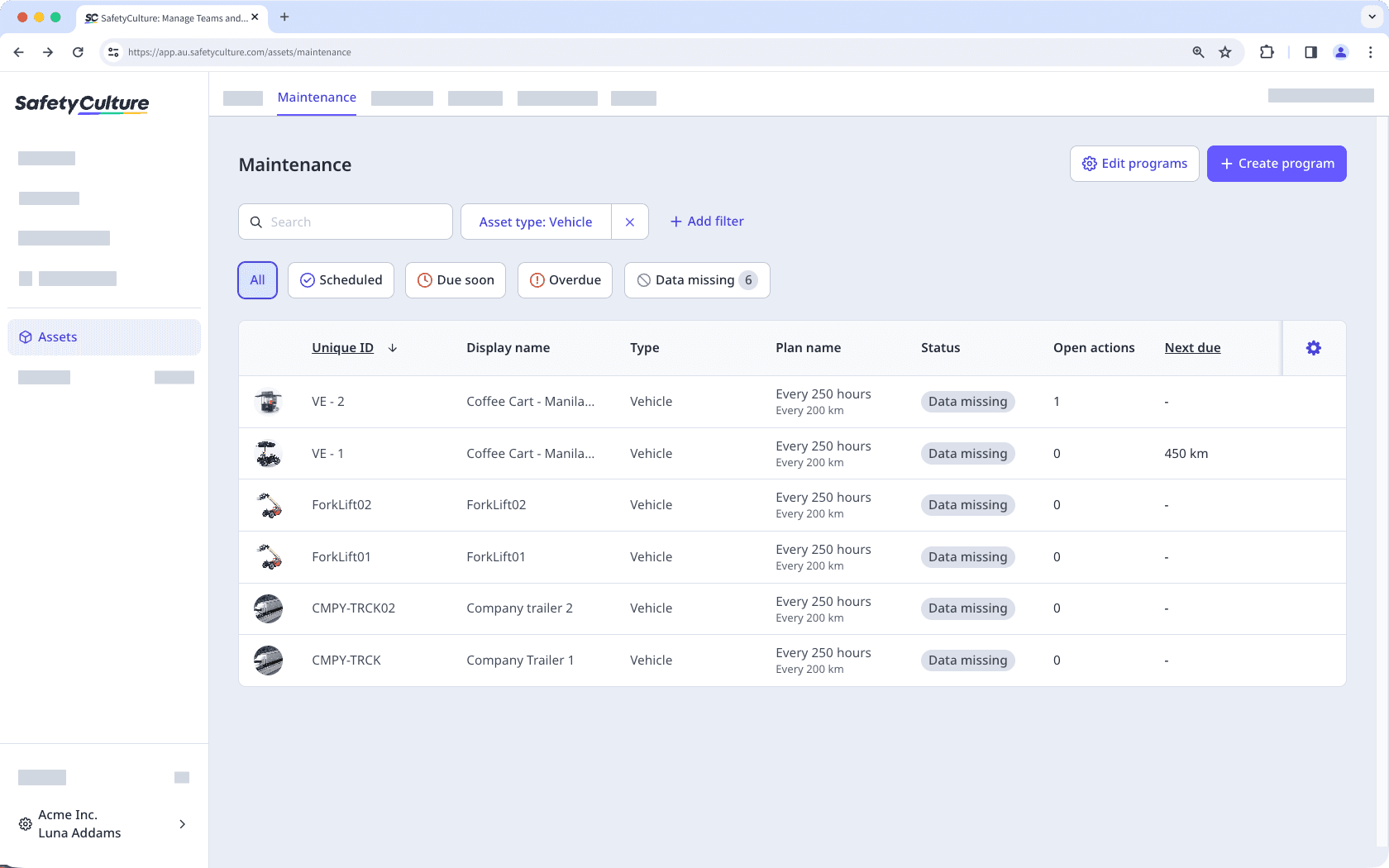

You can view plan statuses in two main areas:

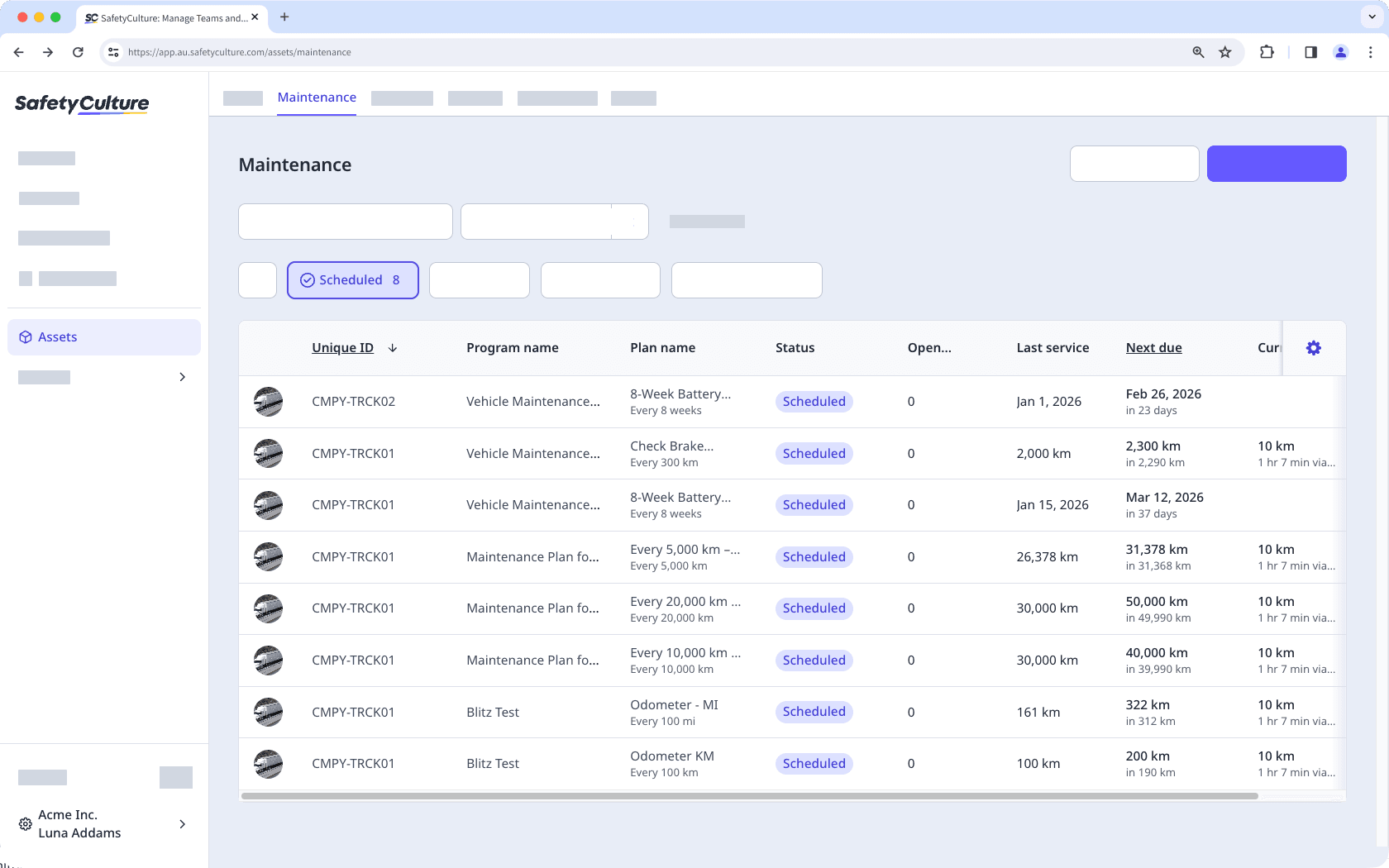

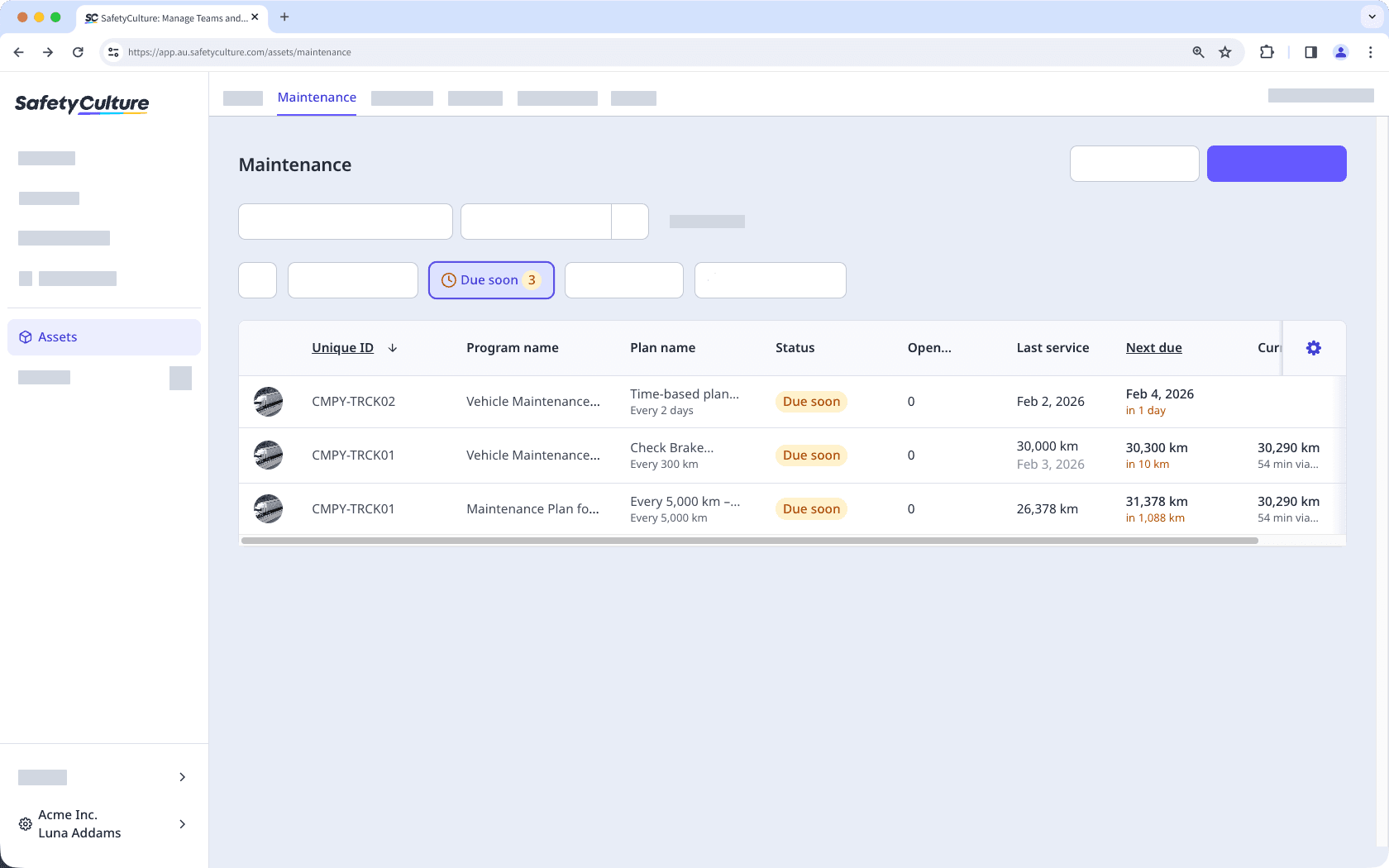

The maintenance table in the Maintenance tab, where you can filter by status to quickly see which assets need attention.

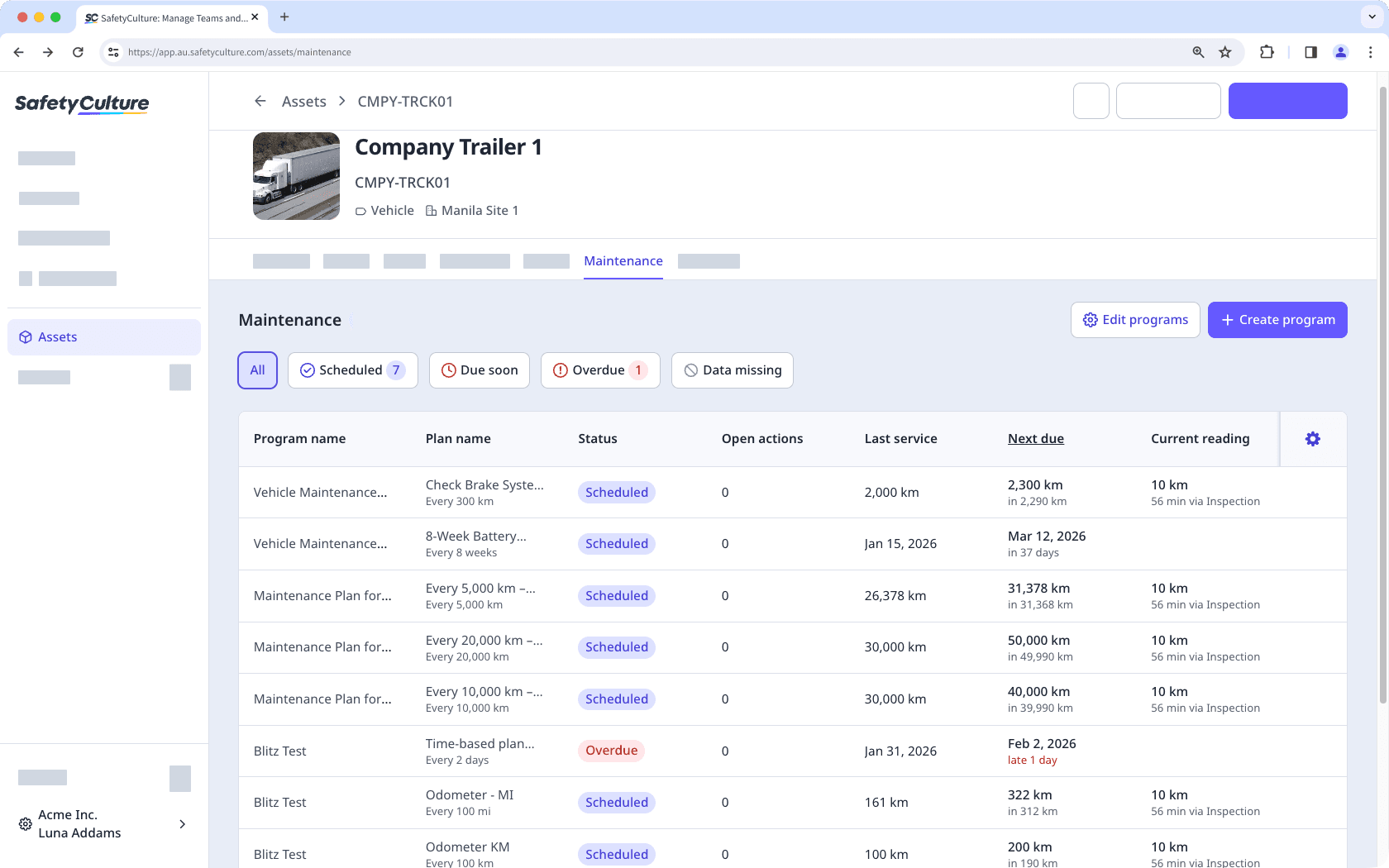

The asset profile, which shows plan details and current status for each asset.

Exploring asset maintenance plan statuses

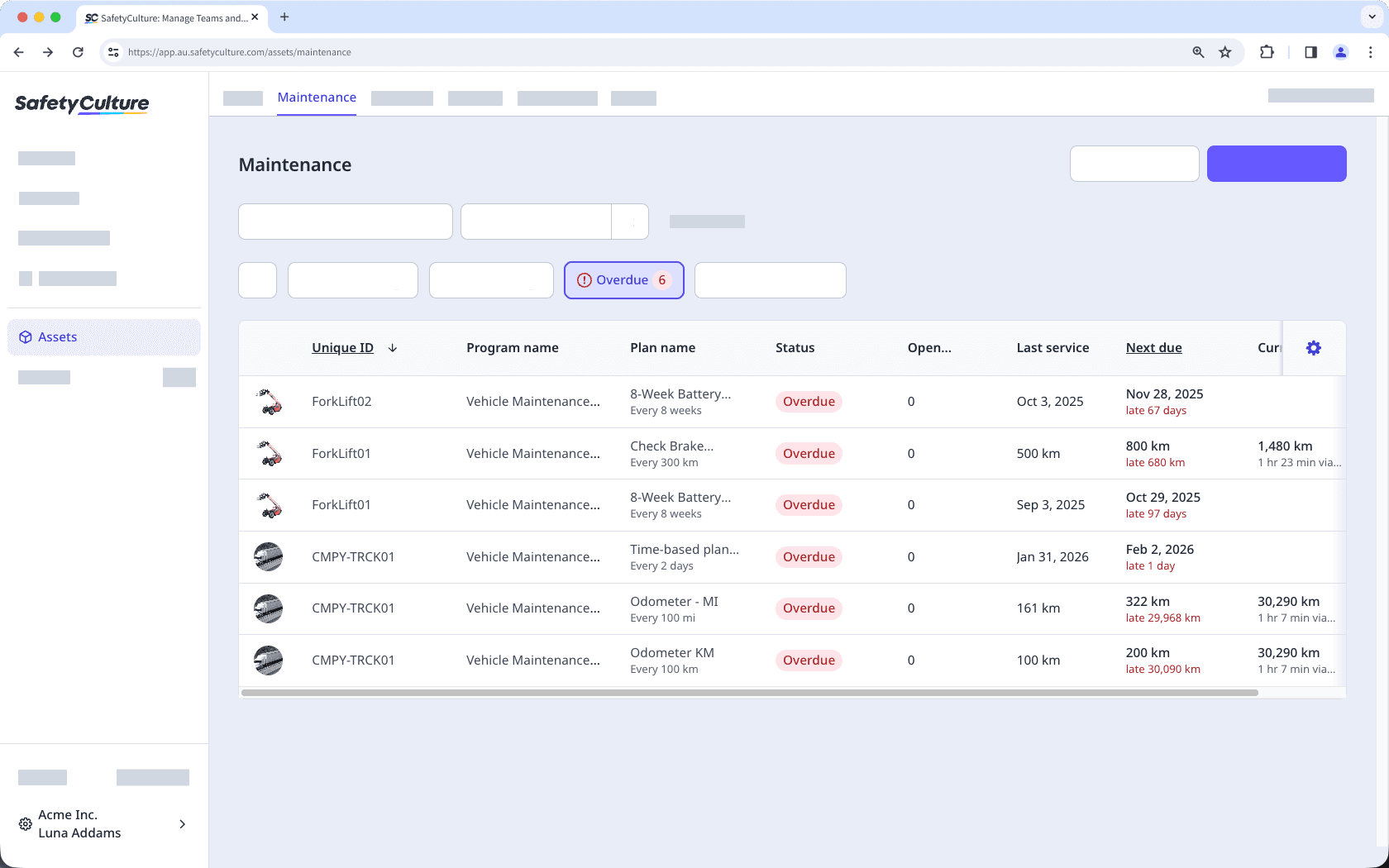

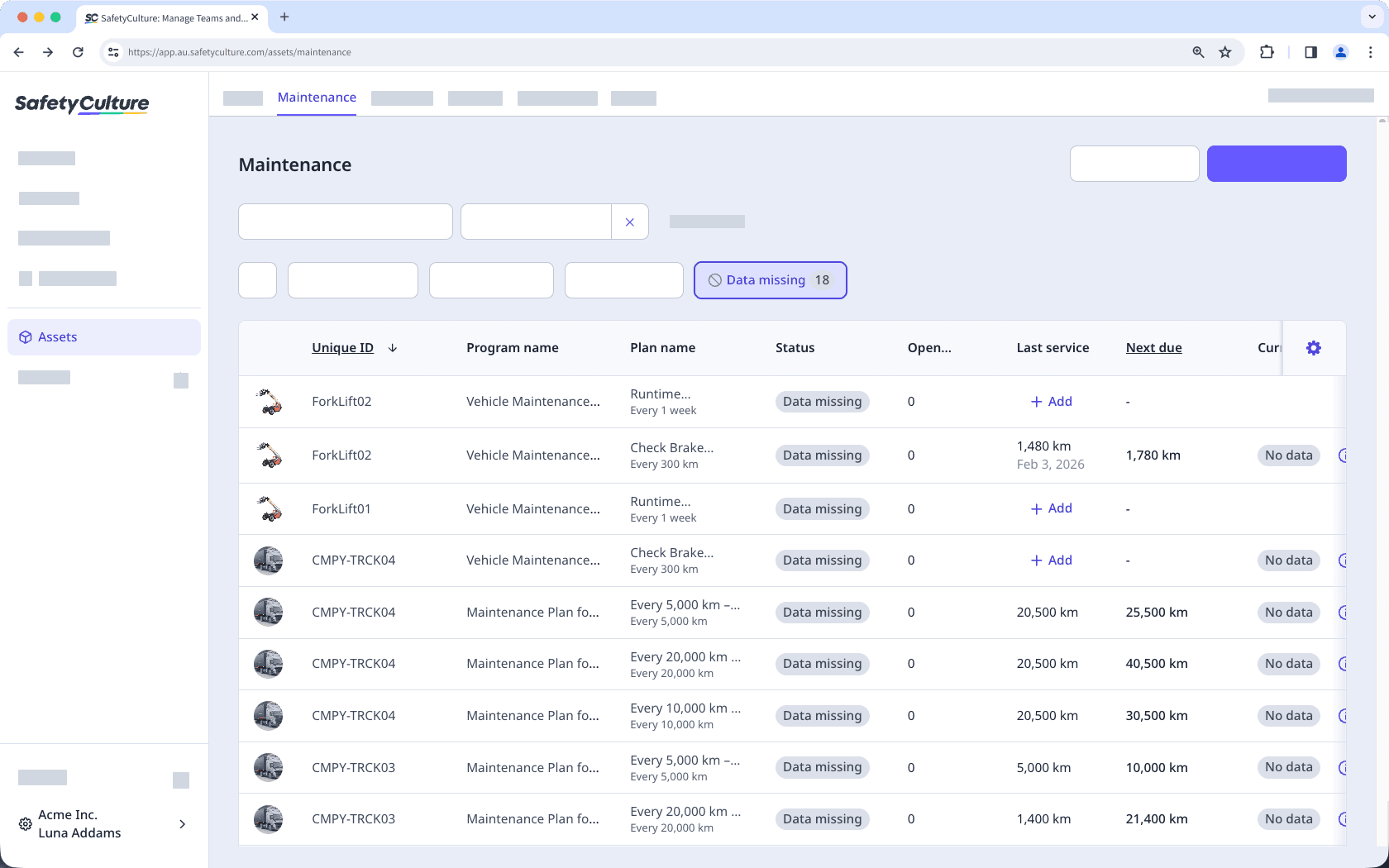

There are four plan statuses that help you understand where each asset is in its maintenance cycle: Scheduled, Due soon, Overdue, and Data missing. Teams can use the maintenance table to view and manage all plans.

Scheduled

The “Scheduled” status means the maintenance plan is active, but the asset is still within the acceptable usage range or time window. No immediate servicing is required.

For admins, this is a good indicator that maintenance programs have been set up correctly, usage readings or time intervals are being captured properly, and the plan is functioning as intended.

For team members, this status acts as reassurance that the asset is being tracked. However, it is recommended they continue monitoring usage or time to ensure the plan transitions into “Due soon” as expected. No action is needed yet.

For example, a delivery truck has its oil change plan set to every 10,000 kilometers or every 90 days. The vehicle currently sits at 7,200 kilometers and was serviced 30 days ago, its plan remains "Scheduled".

Due soon

The “Due soon” status means the asset is nearing its defined time or usage threshold. It signals that servicing is expected shortly and allows teams to prepare for upcoming work.

For admins, it highlights upcoming maintenance so they can validate alert thresholds and coordinate work in advance, especially for assets that need downtime. They can customize when “Due soon” appears by adjusting the alert threshold on each plan.

For team members, this status signals them to review the plan and either begin assigning actions or monitor it closely.

For example, forklift requires servicing every 250 engine hours. It has now reached 240 hours, triggering the “Due soon” status so the team can schedule work before it becomes overdue.

Overdue

The “Overdue” status means the asset has passed its set maintenance interval and is now beyond the acceptable usage or time range. This status highlights work that should be addressed immediately.

For admins, overdue plans can indicate gaps, like missed readings or team coordination concerns. Admins should monitor these cases and adjust maintenance plans or team workflows accordingly.

For team members, plans with this status becomes their priority. These often indicate high-risk equipment that needs immediate servicing to avoid failure, safety concerns, or downtime.

For example, a generator is scheduled for inspection every 30 days. It was last serviced 45 days ago but hasn't been maintained yet. The plan now appears as "Overdue".

Overdue plans stay visible until maintenance is completed and the plan resets. Tracking these in the maintenance table helps teams resolve critical work and maintain service history accuracy.

Data missing

The “Data missing” status appears when a required detail is missing, such as a last service date or the most recent odometer or runtime reading. Without this baseline, SafetyCulture can’t calculate when the next service is due. Until the required data is provided, the plan status will remain blocked.

For admins, this status helps identify incomplete setup or missing data across programs. It’s often an indicator that new assets were added without service history or integration issues need resolving.

For team members, they should update the missing data as soon as possible so the system can generate a meaningful plan status. This could mean logging a reading via inspection or adding the last service details.

For example, a new excavator was added to a plan that triggers every 500 kilometers, but it has no initial odometer reading. As a result, the plan shows “Data missing.”

Cette page vous a-t-elle été utile?

Merci pour votre commentaire.